The technicians and engineers at SOTRALENTZ Construction in France and Germany form a constant alliance between the expertise developed in the company over the years and their own technical competence.

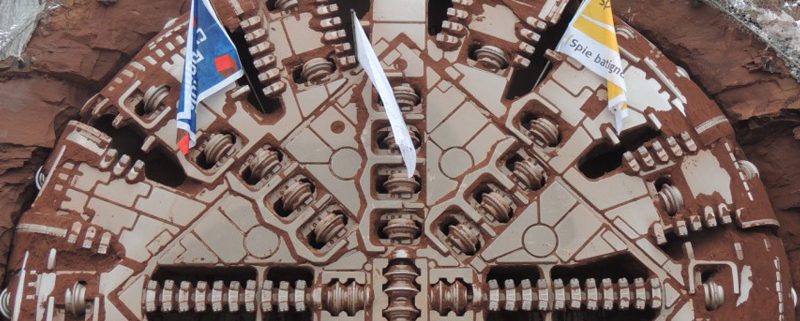

The result is a profound ability to satisfy customer requests, or even anticipate them, from the engineering study to delivery or implementation. Between tradition and continuous innovation, they know how to anticipate your requirements and provide you with solutions, design study on delivery or on implementation for the manufacture and optimisation of your special welded wire-meshes, shaped armature cages, voussoirs.

Some references

– European Parliament in Strasbourg, Alsace

– Airports at Roissy-CDG, Toulouse, Bordeaux etc.

– Stade de France- Tunnels of Kinding (Germany), Uetliberg (Switzerland), Liefkenshoek (Belgium), Socatop A86, etc.

– Public hospital in Strasbourg, Alsace

– Hospital of Clermont-Ferrand

– Waste water treatment plant in Achères and Creil

– Viaduct of Compiègne

– Oxygen Tower of Lyon

– EPR of Flamanville

Services +

– Special installation operations on site (motorways, raft foundations, etc.)

– An installation service for metro networks and trams (Lille, Toulouse, Rennes metros, etc.)

– A service for special welding on site with certified welders